Let’s look at the specifics of heat shrink tubing material and its roles in protecting mechanical systems.

If you need heat shrink tubing for any application in the El Paso area, call HST Cable Management Products at 1800-880-3212 and learn more about how we can help you.

What is Heat Shrink Tubing?

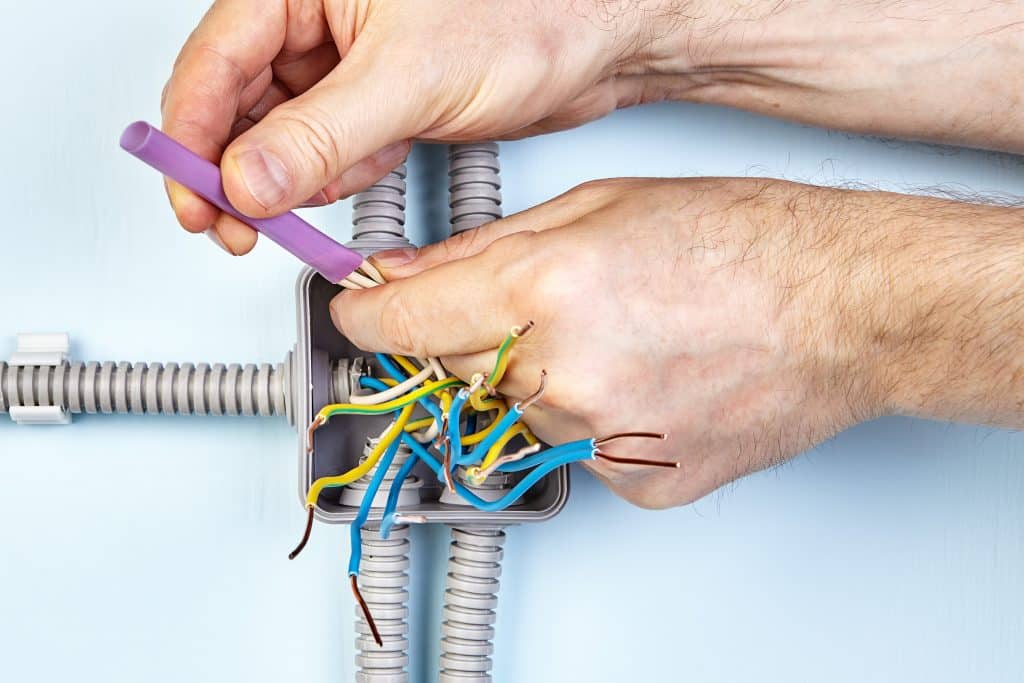

If you’ve ever seen a bundle of cables or computer wiring in a large office, you’ve likely seen heat shrink tubing in action, although it is quite conspicuous once it is installed. Heat shrink is a type of shrinkable plastic tubing that protects electrical wiring. The material is specifically designed and manufactured to shrink when exposed to heat so that it snugly wraps around the cable and creates a protective barrier that shields the wire beneath.

So while there are various kinds of tubing specifications, they all share the shrinking property in common. When heat is applied, they conform to the shape of the cable they envelop, thereby creating a tight seal.

The first iteration of heat shrink tubing came around the 1950s by Raychem Corporation. Paul Cook, a chemical engineer, used radiation chemistry to develop the material. Cook experimented with cross-linking polymers. His experience with this cross-linking and with radiation meant that he could change the thermal properties of the plastic.

Industries use heat shrink for a wide range of applications like wrapping, insulation, or protective functions. Industries that use heat shrink tubing include:

- Automotive

- Aerospace

- Apparel

- Medical

- Military

- Telecommunications

- Marine

- Appliances

- Manufacturing

The Development of Heat Shrink Tubing

Chemical engineers experimented with early formulations and have added specialized treatments to heat-shrink tubing over time. Adding colorants, for example, became a popular addition to the material, as it helps users organize and color code their cable assemblies while protecting them at the same time. In addition, UV blocking compounds are also added for tubing that is specially formulated to sit outdoors for long periods of time and, therefore, subject to the degradation of UV rays.

What are the Main Functions of Heat Shrink Tubing?

This flexible material has an important job in the day-to-day operations of several industries. Thanks to the unique makeup of the material and the clever science behind it, this tubing protects important cabling systems, terminals, loose wires, and more. Its main functions are:

- Protection: Its first essential function is protection. The material around the cables simply provides an added layer of protection and prevents corrosion or damage.

- Insulation: Because of how tightly the tubing wraps around the cables, it provides additional protective layering. This becomes especially important when cables run hot all day, carry a lot of energy, or are installed where there are unpredictable or harsh environmental conditions.

- Organization: In complex mechanical systems, several cables and wires run together in close quarters. This setup can make it difficult to tell which cables are which, and heat shrink tubing plays a role in organizing these cables for easy access.

- Structural support: When properly installed, heat shrink tubing serves cable management purposes that provide structural support to systems and minimize strain.

- External protection: Some cables run outdoors, indoors, or are housed in a tightly compacted engine surrounded by other mechanical components. The added layer of protection provides a shield from the external elements or conditions that are invaluable when it comes to the longevity of any working system.

Throughout different industries and applications, heat shrink tubing serves both a functional and aesthetic, and organizational function. Heat shrink tubing can:

- Protects against water and dust in cable splices

- Insulates wiring and cables front the extreme heat produced in boats, military vehicles, automobiles, and aircraft

- Protect from corrosive chemicals

- Provides color coding for organizational and aesthetic purposes

- Enhance the vast cable bundles in computer case mods

Need Heat Shrink Tubing for Your Industrial or Commercial Applications? Call HST Cable Management Products Today.

For many years, HST Cable Management Products has been working with various industries across the country to supply them with the necessary cable management products. One of our top products is heat shrink tubing, which is a necessary component of most electrical systems today.

With many options to choose from, and different specifications and sizes, it can be difficult to find the right one for you. Call the HST Cable Management Products team today and find the answers you’re looking for.